Reduce rail disruptions through intelligent maintenance prioritization

Industry Sector: Transportation

Business Function: Maintenance & Reliability

A major freight railroad wanted to reduce a large number of service disruptions by reducing turnout failures.

With Foundry, the track maintenance team reduced disruptions through an integrated view of track components across all systems and by taking action in Foundry’s operational applications:

- Prioritized maintenance operations to high risk turnouts

- Designed capital plan based on needs instead of historical spend

- Improved maintenance crews’ trainings based on previous maintenance activities

Challenge

A major freight railroad was experiencing significant service disruptions caused by repeat failures of turnout components. However with 50k+ turnouts, they had difficulties tackling the problems over their entire network effectively.

Solution

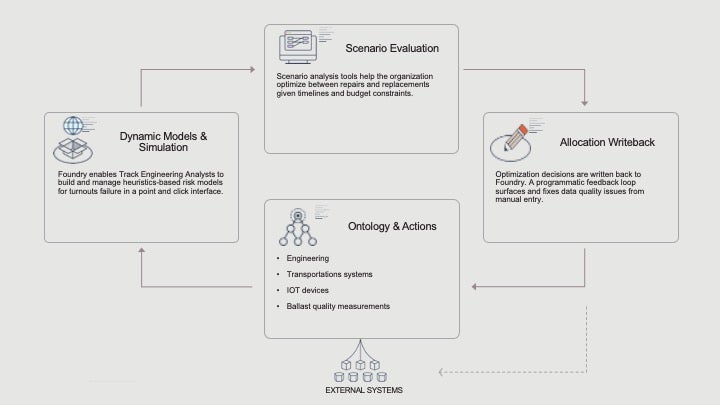

- Integrated Ontology -- Foundry combines all information related to turnouts from engineering and transportations systems, as well as from IOT devices such as geometry and ballast quality measurements from telemetry-equipped railcars. The system provides full context for turnouts maintenance decisions and analysis of past failures.

- Turnout Risk Monitoring -- Foundry enables Track Engineering Analysts to build and manage heuristics-based risk models for turnouts failure in a point and click interface, leveraging metrics from the ontology.

- Integrated Capital Planning -- Foundry connects capital planning process with the unified view of turnouts to drive investments where it’s needed the most. Powerful scenario analysis helps the organization optimize between repairs and replacements given timelines and budget constraints.

- Data Quality Enhancement Process -- A programmatic feedback loop surfaces and fixes data quality issues from manual entry. Integration to the railroad’s ERP system enables the track maintenance crews to quickly submit corrections.

Users and stakeholders

- Track Engineering analysts

- Maintenance Crews

Impact

- Less than 6 months to implement data driven maintenance processes across all geographies.

- A significant percentage of failures took place at turnouts that were proactively flagged high risk.

- Those turnouts were triaged and those that were identified as high risk were prioritized for inspections, repairs, and replacements.

Implement a similar use case

This use case implements the following Patterns. Follow the links below to read more about a particular Pattern and learn how it is implemented within Foundry.

- Operational process coordination (used for 8 other use cases)

- Resource allocation & optimization (used for 3 other use cases)

Want more information on this use case? Looking to implement something similar? Get started with Palantir. ↗