Preventing transformer failure via alerting and investigation support

Industry Sector: Utilities

Business Function: Operations

This use case enables utility providers to schedule and prioritize maintenance tasks. First, a digital twin of the infrastructure is created on Foundry, on which several applications are built to enable faster and more informed decision-making.

Challenge

Facing evolving demand patterns and aging infrastructure, a North American utility provider looked to implement risk-informed asset management strategies. To do so, it needed to measure total risk exposure over its network, identify trends to prioritize maintenance and investment, and accelerate investigations of asset failures and build an asset health database.

The data needed to achieve these goals was spread over many different systems, often with contradicting information. Additionally, most of this data was isolated from the operational decision makers who assessed risk and allocated resources, presenting obstacles to organizational change.

Solution

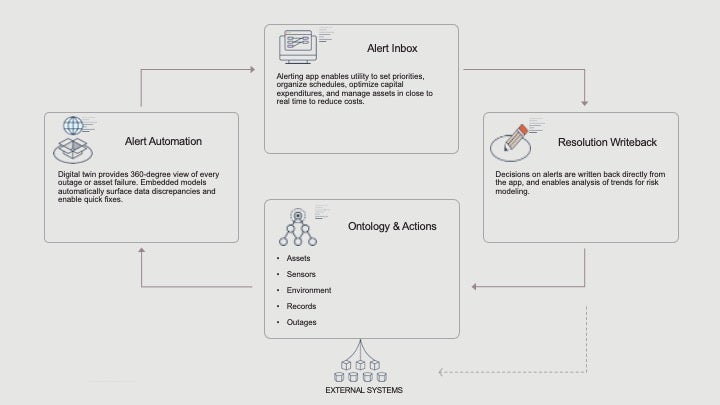

First, a digital twin of electrical assets and historical actions was built. Foundry integrated data from 9 disparate systems, including geospatial and meteorological data, investigation and maintenance records, outages, and asset details. The digital twin produces a high-fidelity picture of every asset and its local environment — from conductors to transformers and switches. Embedded models automatically surface data discrepancies and enable quick fixes. For example, if separate operational systems register two distinct causes for an outage, Foundry alerts on mismatched fields to ensure a highly accurate model of the world.

On top of the digital twin, different investigative and decision-making workflows were built. Foundry delivers a 360-degree view of every outage or asset failure. A no-code visual interface allows users to investigate common failures like cables down or transformer overload and diagnose root cause, taking into account not just asset history but environmental context as well.

Learning loops for continuous improvement. Foundry records actions and decisions from each investigation and enables analysis of trends for risk modeling. In the future, these risk models will generate an asset health score and predict future problems. By capturing past investigations and decisions, Foundry is helping the utility set priorities, organize schedules, optimize capital expenditures, and manage assets in close to real time to reduce costs.

Together, these capabilities are enabling our customer to move to an analytics-powered asset management approach that delivers short-term results while positioning an analytics transformation across the business.

Impact

- The organization now proactively generates lists of high-risk transformers for review and preventative maintenance.

- 120x faster identification of overloaded transformers (days to hours).

- Unified data asset on equipment health drives significant efficiency gains (hours to minutes) in investigations.

How it's made

Assets data digital twin

GIS data is a system of record for asset locations and forms the backbone of the Assets digital twin. This is augmented with Sensor, Environmental, and Outage information coming from many other sources, along with Work Management and Inspection data from SAP systems.

Workshop app for alerting and basic map investigation

Workshop app exposes top-down inbox view of trends or specific outages to investigate, then uses embedded Object Views and built-in Workshop maps to facilitate in-app investigation. Decisions and decision context are captured via writeback directly from the app.

Implement a similar use case

This use case implements the following Patterns. Follow the links below to read more about a particular Pattern and learn how it is implemented within Foundry.

- Alerting workflow (used for 7 other use cases)

- Investigation and cohorting (used for 3 other use cases)

Want more information on this use case? Looking to implement something similar? Get started with Palantir. ↗